AI to the Rescue: Sorting and Recycling Plastic Made Easy

In our brand new Environmental Sustainability (ES) blog series, our undergraduate student guest authors will be discussing all things Environmental Sustainability. This blog will explore how Artificial Intelligence (AI) is being developed to drastically improve the efficiency of plastic waste recycling.

Blog author: Alessandra Sabatini, Undergraduate Student, School of Biological Sciences,

The problem of plastic recycling and plastic sorting

Plastic recycling has been a long-standing challenge for waste management industries. Currently, only 5% of plastic intended for recycling facilities ends up in new products. This low percentage reflects the complexity of sorting and recycling the material. Cross-contamination of materials, water requirements, and associated food waste further exacerbate the problem. Similarly, compostable plastics can only realise their lower environmental impact if sorted away from other plastics and processed in industrial composters.

An AI solution

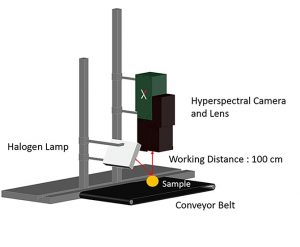

Image of hyperspectral camera system displaying components. From Taneepanichskul, Hailes and Miodownik (2023)

In March 2023, a team led by Prof Miodownik at UCL published in Frontiers in Sustainability details of a machine learning model capable of isolating compostable and biodegradable plastics from conventional fuel based varieties. The team designed a classification system based on hyperspectral imaging (HSI), which scans materials’ chemical signatures to produce a pixel-by-pixel description of samples. They trained a machine learning program on this data, which subsequently sorted individual pieces of plastic waste.

They tested the technology on various plastic types:

Fuel-based and recyclable (although actual recycling is location-dependent):

- polyethylene (PET) [drink bottles, jars]

- polypropylene (PP) [food tubs and containers]

- low-density polyethylene (LDPE) [bags and plastic films]

Bio-based and compostable:

- polylactic acid (PLA) [cup lids, tea bags, coatings for coffee cups, food containers and cartons]

- polybutylene adipate terephthalate (PBAT) [magazine wraps and caddy liners]

Biomass-derived and compostable:

- palm-leaf and sugar cane [packaging film]

The team tested pieces ranging in size from 5-50mm2 and found that their model achieved perfect accuracy in sorting plastic materials larger than 10 x 10 mm (>1 cm2). For smaller items, the model’s sorting rates varied depending on the material. Nonetheless, the initial results showed great promise for the model if honed and scaled up to meet industrial demands.

How will this help us?

Automatic sorting via machine learning has the potential to significantly improve plastic sorting efficiency and accuracy and downstream recycling or composting. The advantages of compostable packaging will only be realized when they are industrially composted (>75°C in machines) and not disposed of in the environment or contaminating waste streams, such as plastic recycling or food waste for compost. If left on a field, the plastics will only degrade very slowly and are likely to leach microplastics.

Automatic sorting is thus a key technology to improve recycling and make compostable plastics a sustainable alternative to recycling. It is urgent to invest in such technologies to optimize them and scale them for industrial use.

Read the original research article.

The content discussed in this article aligns with United Nations Sustainable Development Goals:

- 12: Responsible consumption and production

- 13: Climate action

To find out more about Environmental Sustainability: visit the Faculty’s intranet page, website or contact srbmh@manchester.ac.uk. For more information on Environmental Sustainability at the University watch this short film or visit their website.

0 Comments