The Cancer Research UK Manchester Institute is leading the chill up way…

Blog by Stuart Pepper and Maggy Fostier

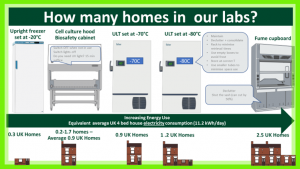

In the lab, the top two energy consumers are fume cupboards and ultra-low temperature freezers (ULTs). Based on a typical 4 bedroom house consuming 11.2 kWh/day in the UK, on average, fume cupboards use the equivalent of 2.5 houses and ULTs set at -80°C the equivalent of 1.2 homes. In FBMH, we have about 170 fume cupboards and 600 ULTs, so we are looking after a small village of >1000 homes.

Fume cupboards consume a lot of energy because they extract and filter air from the lab and reinject air from outside which must be warmed up. Fume cupboards must be left ON all the time for safety, so the best way to save energy is to shut the sash when not in use and declutter the space for safe working and optimum ventilation.

ULTs energy consumption is dependent on whether the door is opened often and the ambient temperature. Every time you retrieve a sample, the temperature rises, and the compressor must work hard to lower the temperature again. ULTs also release a lot of heat, which we currently do not capture (something to think about). Instead we spend more energy to cool them down so that the compressors do not have to work so hard; this is not accounted for in our estimate.

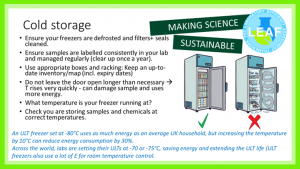

There are several actions you can take to save energy with ULTs and lengthen the life span of the compressor and thereby the freezer. The first one is easy: ensure your freezers are well maintained and establish an effective sample records system and racking to minimise sample retrieval time. The next step is time consuming at the onset but will save time in the long run: minimise storage space by removing any unnecessary samples, consolidating and using smaller containers when possible. The final step is very easy: chill up by setting the temperature at -70℃.

Until relatively recently all freezers were set at -65℃ or -70℃ and the types of samples being stored have not changed significantly. The storage temperature decreased because manufacturers designed compressors which could reach lower temperatures. Marketing brochures argued that lower was better, but these claims were not evidence -based. Many Institutions have switched back to -70℃ or -75℃ and the LEAF silver level encourages labs to consider chilling up. It is a big decision to be taken by PIs, sometimes jointly owning freezers and it may require an agreement with regulators such as the HTA, so we have put together a short powerpoint to review the evidence on chilling up found in the literature so far.

Stuart Pepper who is leading the LEAF accreditation for the Cancer Research UK (CRUK) Manchester Institute, has decided to embrace the chill up movement. They have 61 ULTs and they have switched 55 ULTs to -70℃. They wanted to calculate the impact of their action, so they monitored two freezers that were in normal use over a period of a week whilst set at -80℃, then while set at -70℃ . Their measurements showed an average saving of 2.7kWh per freezer per day, saving the equivalent of 13.3 x UK 4 bed homes (average electricity consumption is 11.2 kWh/day). One challenge has been where work falls under regulatory requirements (e.g. clinical trial work) and there was a need to update SOPs. They now have ~90% of their freezers at -70℃ with the aim of getting close to 100% over the next couple of years. Please do contact Stuart (Stuart.Pepper@cruk.manchester.ac.uk) if you want more details.

If you would prefer to carry out some tests before switching the temperature of your freezers, please contact May Tassabehji (m.tassabehji@manchester.ac.uk) who has started a long term project of testing sample integrity at various cold storage temperatures.

To find out more about Environmental Sustainability: visit the Faculty’s intranet page, website, read our ES Good Newsletter or contact srbmh@manchester.ac.uk . For more information on Environmental Sustainability at the University watch this short film or visit their website.

0 Comments